Case Study: 58th Special Operations Wing Human Performance Facility

When the 58th Special Operations Wing (58th SOW) set out to build a Human Performance Facility at Kirtland Air Force Base, they were not looking for a typical equipment order. They were trying to solve a tactical readiness problem inside a repurposed room with real constraints: limited square footage, complex corners and clearance challenges, and a demanding use case where athletes need to move efficiently, safely, and at scale.

What made this project different is the way it started. The 58th SOW leadership did not want a generic layout. They wanted a training environment that matched how operators actually train, while still reflecting the culture and identity of the unit. This facility needed to feel like it belonged there, not like a random gym dropped into a military space.

That is exactly where Samson’s design process became the turning point. The final build was custom in every sense of the word, because it had to be. Every corner mattered. Every storage decision mattered. Every training lane mattered. And most importantly, the chain of command needed to see the end result clearly before committing, which is why Samson’s 3D layout design process played such a major role in the project’s success.

If you want to see the finished facility and the full project overview, visit the Samson facility page: Military Weight Room: Case Study: 58th Special Operations Wing (Kirtland AFB).

The mission and the real constraint

Training tactical operators efficiently is often a tough challenge when facilities are not equipped and designed properly. Unlike a standard commercial gym, a military Human Performance Facility has to support high utilization, high standards, and programming that spans strength, durability, power development, conditioning integration, and injury reduction. The facility must also work for multiple training groups and schedules, not just one team.

Now add the most common reality in government facilities: sometimes the room is not purpose-built. It is repurposed. That means your constraints are not theoretical. They are physical. Corners, walls, columns, tight passageways, and odd dimensions are not design “problems” to ignore. They are the reality that determines whether the room works or fails.

For the 58th SOW unit, the challenge became an opportunity. They put Samson’s customization capabilities to the test by utilizing the Flex-Rack Series foundational frame to maximize floor space and training areas within the room’s limited footprint.

From “that can’t be done” to “we’ll do whatever it takes”

The customer’s experience is one we hear often from serious programs: leadership identifies a specific capacity target, asks vendors if it can be done, and gets told “no” because the request does not fit a standard offering.

In this case, the 58th SOW leadership asked for a specific number of rack stations. Several companies responded that the request was not possible within the available space. Samson responded differently. The approach was not to compromise the vision immediately. The approach was to engineer the layout so the room could do what the mission required.

As the customer described it, this project was not “regular stock.” It was a true custom build. Every corner was considered. Every “nook and cranny” mattered because the room had to be used daily, by real operators, for years to come.

Why 3D layout designs mattered more than most people realize

Many companies can sketch a 2D plan. Fewer can translate that plan into a detailed 3D design that accurately reflects how the equipment will fit, how the room will flow, and how training lanes will work in practice.

In military environments, that visualization is not a luxury. It is often the difference between a stalled project and an approved project. The reason is simple: purchasing decisions rarely involve one person. There are stakeholders across the chain of command, and it is hard to “sell” a facility with words alone.

The customer said it directly: in the military setting, it is difficult to secure buy-in when you only talk about what a room could become. The 3D renderings made the plan tangible. Instead of asking leadership to imagine the result, the customer could place visuals in their hands and show exactly what was being built.

Samson’s process is designed for this reality. It starts with real requirements, then moves into layout planning, then into a 3D representation that helps stakeholders clearly understand the final outcome. If you want to learn more about how Samson approaches facility planning, explore Custom Solutions and browse additional projects on the Samson Facilities page.

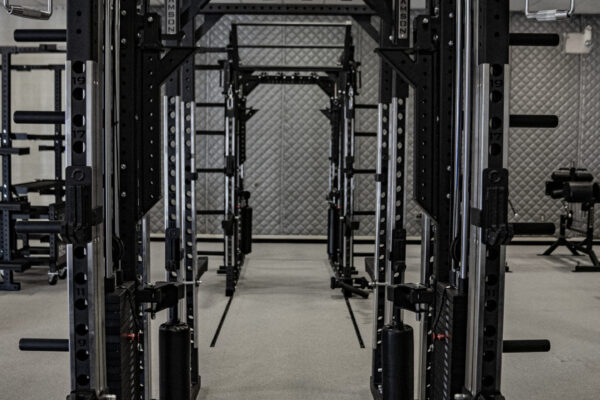

The layout solution: eight custom Flex-Rack stations built for throughput

The completed facility features a total of eight custom Flex-Rack units. Each Flex-Rack contains a Functional Training Rack (FTR) attached to a 6-post Power Rack. This configuration was selected because it supports high training density without turning the room into chaos.

In practical terms, each station can support 6 to 9 operators at a time. Across eight stations, that is up to 72 tactical athletes moving through training stations throughout the room. That throughput is not accidental. It is a direct result of designing the stations as complete training environments rather than isolated pieces of equipment.

The stations were equipped with chin bar solutions that support multi-user training. The FTR units use Samson’s Fly-Away chin bar design, while the Power Racks feature the standard Multi-Grip chin bar. Pulling strength is a core requirement for tactical readiness, and high-volume pull work demands a setup that supports efficient rotation and consistent station flow.

One section of the facility required a completely custom monkey bar connecting link. This is a perfect example of why custom manufacturing matters. When a facility needs a specific movement pattern or training feature, the room should not be forced to compromise simply because something is not available “off the shelf.” In this project, that custom link helped complete the training ecosystem in a way that matched the needs of the operators and the vision of the Human Performance leadership.

Designing for limited space means designing for storage

With extremely limited space inside a repurposed room, being creative with storage was not optional. It was essential. Storage determines whether a room stays usable over time or slowly becomes cluttered, unsafe, and inefficient.

For the 58th SOW facility, each custom link was equipped with extra barbell storage, shelving, and custom rolling carts made for HAVAK Triad dumbbells. These decisions are the kind that matter after installation, when a room is used every day and equipment must be returned to a consistent place. In high-use environments, strong storage planning is part of training performance because it reduces wasted time, minimizes clutter, and supports safer movement throughout the space.

Samson also builds a wide range of storage and facility support solutions that can be integrated into a complete design plan. To explore more options, review Samson’s product categories via the Samson Equipment sitemap and the relevant storage and accessories sections.

Branding and cultural fit: the facility had to look like it belonged

Military environments are unique. There is a certain look and identity tied to each branch, each unit, and often each mission set. The customer highlighted that this was a meaningful part of the project. The design and culture of the facility needed to match where the operators are, and what their unit represents.

Custom branding throughout the room was designed with intent and purpose to encourage operators to use the facility daily and to support the credibility of the Human Performance staff. In an environment where readiness is the goal, daily utilization matters. A room that looks generic can feel optional. A room that looks like it represents the unit feels like part of the mission.

The customer also emphasized the deeper “why” behind the project: the facility needed to represent the idea that humans are more important than hardware. That mindset aligns perfectly with Human Performance programs. The purpose is not the equipment itself. The purpose is what the equipment enables: stronger, more resilient people who can do the job.

Accessories and training capability: building a complete ecosystem

This room was equipped with an abundance of Samson accessories designed to support variety, durability, and programming flexibility. The facility includes Samson attachments such as Dual Malak attachments, Jammer Arms, Safety Straps, Single Leg Squat attachments, Band attachment pegs, and bands.

Two new products were also designed and rolled out as part of this project: Belt Squat and Monolift attachments. That detail matters because it highlights a deeper truth about custom rooms: sometimes a facility does not just require custom sizing or unique layout decisions. Sometimes it requires purpose-built solutions that do not exist yet in standard form.

When a manufacturer is willing to engineer new attachments in response to real-world needs, the customer is no longer constrained by catalog limitations. The room can evolve into exactly what the program demands.

Integrating best-in-class vendors while keeping one cohesive plan

A strong facility is often a combination of the best tools available, not a single-brand checklist. Great brands and vendors helped round out this room, including Kabuki Strength, Spud Inc, Concept2, Havak Triad, Dynamax, Tsunami Bar, Rogue Fitness, and Troy Barbell.

Here are a few of the external vendors referenced in the project:

In a high-performance tactical environment, the goal is not to fill a room with “stuff.” The goal is to assemble a system that supports training outcomes. Samson’s design approach made that possible by ensuring that the equipment, accessories, storage, and movement lanes all worked together inside a single cohesive plan.

Procurement reality: responsiveness is part of performance

The customer made another critical point: buying in a military environment can be complicated. The process is rarely straightforward, and timing matters. When approvals, specs, and purchasing requirements stack up, projects can stall.

In this project, Samson’s responsiveness helped keep momentum. The customer described Samson being on the phone and ready to provide whatever specs, details, and support were required to move the project forward. That level of partnership is not a footnote. It is often what determines whether a project makes it through the approval process.

Just as importantly, the 3D layouts reduced friction across the chain of command. Instead of relying on long explanations, the customer could show leadership what the room would look like, how it would function, and why it was worth the investment.

Results that matter for tactical leaders

At the end of the project, the value was measurable in practical outcomes that matter for real training environments:

- Higher training capacity inside a limited footprint, with up to 72 tactical athletes moving through eight custom stations depending on session design.

- A layout engineered around station flow, movement lanes, and utilization, not just equipment placement.

- Storage built into the design so the room stays functional and organized over time.

- Custom branding and cultural alignment that supports daily use and reinforces the purpose of Human Performance inside the unit.

- A design process that enabled leadership buy-in by making the future facility visible through detailed 3D renderings.

The customer also spoke to the long-term mindset behind the facility. This room is going to be there longer than most individuals will be assigned to the unit. The design needed to stand up to that reality. It needed to be durable, usable, and representative of what the unit stands for.

Customer quote

“Working with the military it is hard to purchase anything directly. Samson was willing to work with other companies to make the process happen in a timely manner and to get everything we needed. We’ve gone further than I ever imagined or that I’ve ever seen in a weight room. There are things that I never really thought of if I would have just went with a regular joe off the street. With Samson, everything is customizable. It really is crazy to say but your dreams come true. Not just to make it happen but the expertise, and the knowledge from the Samson staff themselves allowed us to get there. You need people with a performance mindset and Samson has that.”

Justin Schwind

Why this case study matters as Human Performance grows across the military

As the Human Performance sector grows within the United States Military, more units will face a similar challenge: how to build a high-capability facility inside real constraints, while still meeting high standards of readiness, safety, and identity.

This project is a clear example of what works:

- Start with mission outcomes, not a generic product list.

- Engineer the layout to fit the space, including corners, lanes, and storage.

- Use 3D renderings to align stakeholders and support approvals.

- Build stations that support throughput and real programming needs.

- Design a room that will stay functional and meaningful for years.

To explore more facility projects or start the process for your own space, review Samson Facilities and learn about Samson’s Custom Solutions. If your program is specifically considering a rack-based foundation similar to this project, the Flex-Rack Series is a strong place to begin.

As always, the goal is not to build “a gym.” The goal is to build a Human Performance Facility that improves readiness by serving the people who will use it every day.