Materials

Steel specs

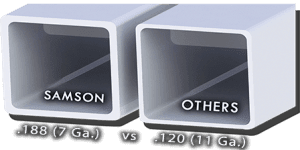

Take a look at the steel tubing comparison to the right between .188 wall and .120 wall. The competition leaves much to be desired.

To evaluate equipment properly, you must understand steel terminology and specifications (specs). This allows you to classify and compare companies. The industry will refer to a “gauge”, this is the thickness of the steel wall. We use 7 gauge steel, which is equivalent to 3/16″ (.188″) thick wall on all of our pieces. You will also see numbers such as 3×3, 2×2, and 4×3. These numbers refer to the relative size of the square tubing in inches. For example, we use 3×3, .188 square tubing on our racks, this means we use a 3″ x 3″ tube with 3/16″ (.188″) thick walls. More material = more strength.

Sealed Ball Bearings

Samson uses precision ground lineal ball bearings in 1”, 1.25”, and 1.5” diameters. Our bearings give a smoother ride than bushings on our top-of-the-line Rockwell 70 – case-hardened, solid steel guide rods. Samson lineal bearings are superior to bushings used by competitors.

Samson rotary bearings last longer, rotate smoother, and carry an eight year warranty. Samson precision ball bearings simply beat the competitor’s bushings in performance and durability.

Durable Upholstery

We use 40oz. Texhyde Premier vinyl on all of our padding. The expanded back and thickness is what makes it Samson Strong, unlike the 18-28oz. fleece-backed competition. Samson also goes the extra mile by double stitching and rounding off the corners, which prevents tears and weak areas on your upholstery.

heavy duty Stainless Steel

All Samson adjustable parts are made of 2″ x 2″ stainless steel, which is then polished to a bright mirror like finish. The Samson finish is forever, unlike chrome plating, which will eventually chip.

We use stainless steel rack shields on your uprights to protect your powder coat finish as you adjust your J-cups, safeties and attachments over the years. Because of its lifetime durability, all Samson equipment now features this stainless steel on all adjustable pieces.

Closed cell neoprene padding

We use extremely dense, closed cell neoprene foam that provides you with an added layer of durability on your upholstery. The quality of closed cell neoprene foam is far superior to rebonded foam commonly found in products across the industry.

Powder Coat finish

All Samson equipment is sandblasted and powder coated using the Sure Coat® Powder Coating system. This gives your product a high quality finish to be proud of.

Manufacturing

Collaborative Design

At Samson Equipment, we believe strongly in the value of shared expertise, and we welcome input from our customers. Moreover, this collaboration begins before the first piece of steel is even cut. Thanks to innovative three-dimensional design technology, we can create fully customized equipment that satisfies your unique strength-building requirements, right in front of your eyes. After 40+ years in the business, we’ve built just about anything you can imagine. If you’ve got an idea that will help your athletes excel, then let’s work together and build a custom piece that accomplishes your goals.

MATERIALS, PREPARATION, & FABRICATION

Once the blueprints are finalized, we prep the raw materials. First, we cut and drill your seven-gauge steel. A build sheet is adapted from the final, approved design and a production schedule assigned. The build sheet, showing any customizations, is then welded by hand. Once your product is fabricated it is sent through sandblasting!

PREP AND PAINT

Next, steel components are powder coated to the color(s) you specify, in a process known as “shoot and bake.” We have hundreds of color options, and unlike many competitors, we don’t charge extra for custom colors. The powder coating is sprayed on and then baked at 400 degrees for 45 minutes, ensuring a durable, shiny and scratch-proof finish.

UPHOLSTERY AND PRE-ASSEMBLY

In the final step of manufacturing, upholstery is hand stitched and securely fitted over 1” thick neoprene padding. Then, the completed components are assembled, inspected and then unassembled for packing and shipping. This is a standard process – each piece of Samson Equipment is fully assembled to make sure everything is included and all customizations are built to specification, before it leaves our facility.

SHIPPING

Samson Equipment offers a number of convenient and economical shipping and installation options, no matter where your weight room is located on the globe. If you need our professional assistance in setting up your new equipment, we offer full, turn-key installation or supervised installation for a very economical fee. If you don’t need our assistance, we offer dock-to-dock shipping. All Samson Equipment is backed by Samson Lifetime Warranty.