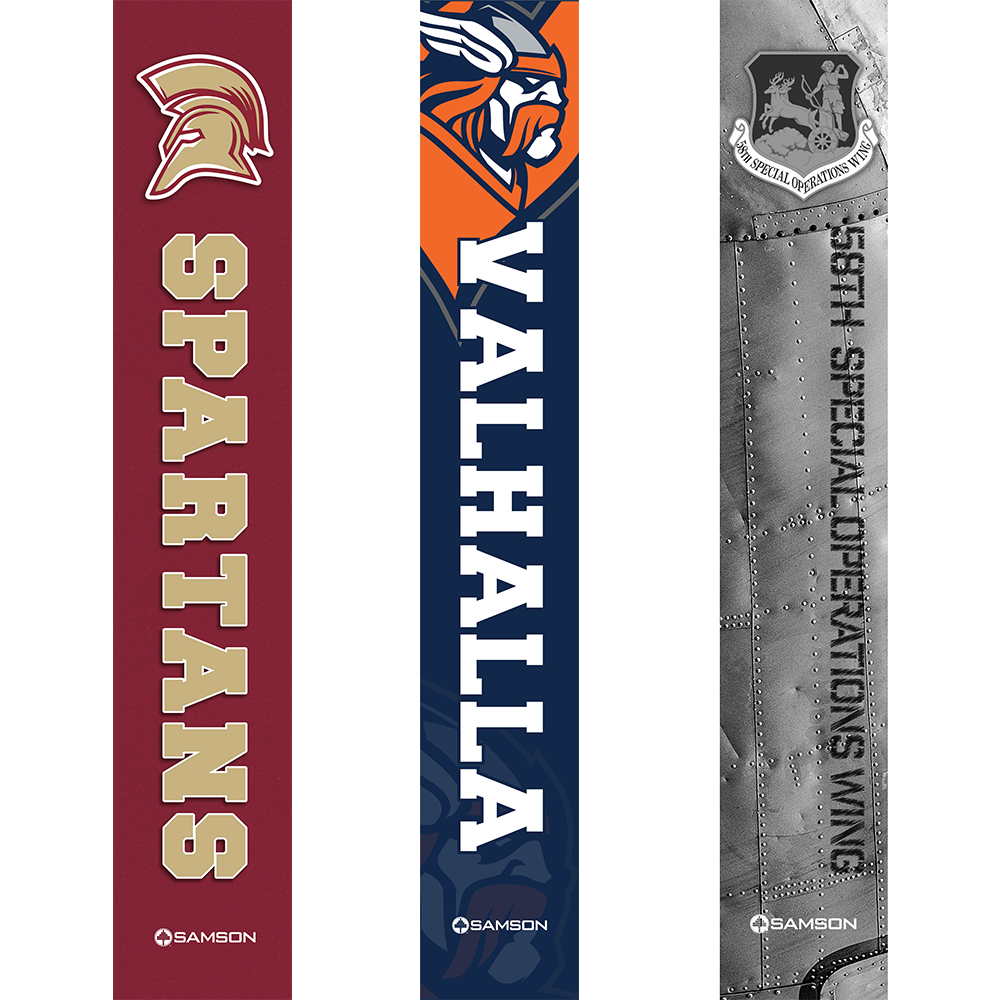

Samson Graphic Shields bring your team’s identity to every rack. Custom printed, laminated, and heat-applied, each shield is bolted to the Flex Rack frame for unmatched durability and visual impact.

Description

Samson Graphic Shields bring your team’s identity to life on every rack. Custom printed, laminated, and heat-applied, these shields are secured with nine bolts to our Flex Rack frame for unmatched durability and a lasting visual impact. Each shield is built to withstand daily training while showcasing the pride and tradition of your program.

We run a professional, end to end branding workflow in house. That means consistent color, crisp detail, and a finish that stands up to years of training. No shortcuts. No guesswork. Just your logo, executed the right way.

What you get

- Custom printed, laminated graphics heat applied to shield panels

- Exact color and line accuracy from vector artwork

- Nine bolt mounting to the Samson Flex Rack frame for a rock solid fit

- Durable, easy to wipe clean surface that resists scuffs and UV

Our production process

Every set of shields follows a precise sequence to lock in quality and longevity.

- Art intake and prep in Illustrator. We start by cleaning up customer artwork, fixing edges, tightening typography, and converting to proper vector paths. This ensures sharp lines at full scale.

- Color management. We confirm brand colors and build a print profile so your reds, blacks, and gradients land exactly where you expect.

- Vectorizing and preflight. Raster logos are vectorized when needed. We create cut paths, bleeds, and registration marks for perfect alignment.

- Print and cut on Roland VersaCAMM VS-540i. Wide format print and contour cut delivers high fidelity color, clean edges, and repeatable results across multiple racks.

- Lamination on Royal Sovereign RSC-1401CW/SP. A clear protective film adds UV resistance and abrasion protection while giving the graphic a smooth, professional finish.

- Final trim and surface prep. We de-mask cut edges, chamfer corners where needed, and clean the shield surface for optimal adhesion.

- Heat application and bond. Using a controlled heat gun process, we activate adhesive and work the laminate into the shield, eliminating bubbles and sealing edges tight.

- Nine bolt mount to Flex Rack frame. Shields are secured with nine bolts to the rack upright, distributing load and preventing vibration or rattle under daily use.

- QC and match set verification. We inspect color, alignment, fasteners, and finish across the full run so every rack looks consistent on day one.

Built for daily use

The laminated face resists chalk, sweat, cleaners, and contact. Wipe down with a mild solution after sessions and your shields keep their pop for seasons.

Proven in the field

See custom shields in action at these Samson facilities:

- Southeastern Oklahoma State University

- University of West Florida

- Moriarty High School

- Andress High School

- Saint Mary’s College

- University of Colorado Boulder

- 58th Special Operations Wing

- Miami University

- Lawrence High School

- Widefield High School

Why Samson

This is not an off the shelf decal. It is a professional branding system engineered to live in a high traffic, high touch environment. The print, laminate, and heat bond work together to protect your artwork. The nine bolt pattern makes the shield part of the rack, not an accessory that loosens over time.

How to order

Send us your vector artwork or high resolution files and your color targets. We will return a proof for sign off before printing. Need a quick refresh down the road? We maintain your files for future runs so a replacement matches the originals perfectly.

Make your room unmistakable. Lock in your identity with Samson Graphic Shields.

- Printer: Roland VersaCAMM Print & Cut VS-540i

- Lamination: Royal Sovereign RSC-1401CW/SP

- Mounting: Nine bolt pattern to Samson Flex Rack uprights

- Finish: Laminated, heat applied graphic with sealed edges

Product Specifications

| Dimensions | 87 × 12 × 0.25 in |

|---|